How to choose the right transformer oil temperature indicator (thermometer)

Transformer Oil Temperature Indicators - also known as electromechanical thermometers or OTIs for short - are essential devices on oil-filled transformers, providing accurate temperature measurement of the oil within. One of the most common questions we get asked regarding these unassuming devices is “How do I choose the right replacement model OTI for an existing transformer?” This is a topic Insulect can help you out with. Read on for more information.

The challenges of replacing an existing OTI

Transformer OTIs normally have a long operational life. But like all devices operating in harsh outdoor environments, they eventually fail. By the time they do fail, they’ve often been in operation for a decade - or several decades. This presents a few problems:

The part number may have worn off or be otherwise unreadable

The brand or model may no longer be available for sale

The operational needs may have changed e.g. now require additional switches, outputs or temperature monitoring capability

There may be a preference for a different brand or technology

There may be an availability or time-sensitive operational factor that requires a different model to be sought

Without a transformer specialist on staff, it may be difficult to understand what is needed

No matter the reasons why, in this article we’ll go through the how to order the correct replacement device.

The 2 types of Transformer Thermometers

There are two basic types of thermometers:

Direct Mount

Remote Mount

Direct mount transformer thermometers

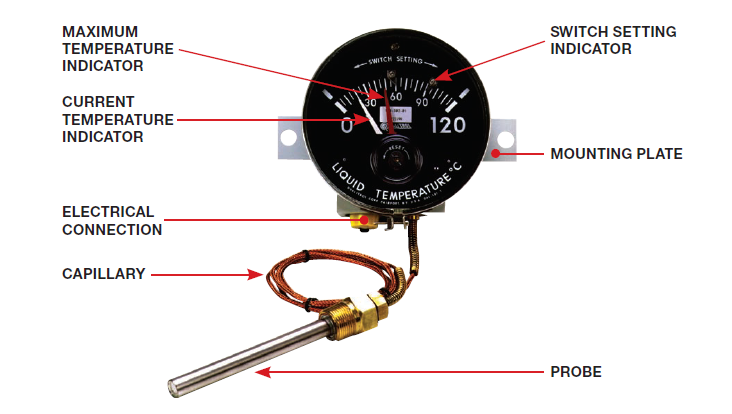

Direct Mount Transformer Thermometers are all-in-one devices mounted directly on the transformer tank. They are commonly located on a side wall (side mount) or on the top (top mount) of the transformer. The design is such that the temperature probe is inserted into a pocket (well) on the tank wall at the mounting point. A direct mount thermometer is fairly easy to identify, as it has a probe coming straight out the back of the device, with the temperature gauge on the front.

Remote Mount Transformer Thermometer

Remote Mount Transformer Thermometers separate the temperature probe from the visual gauge. The probe is inserted into a pocket (well) and a capillary tube connects the probe to the main device and visual indicator. The capillary tube is the easiest way to identify if you have a remote mount thermometer.

Within remote mount thermometers, you could have a winding temperature thermometer or you could have a liquid temperature thermometer. The winding temperature thermometer is going to have a coil that the probe goes into. That coil will be a heater coil that is tapped to a current tap off the transformer.

Thermometer Probe Length, Diameter, Threads

There are a few critical thermometer parameters that you need to know when you're trying to specify a thermometer.

Probe length

Probe diameter

Probe thread size (to screw into the transformer well)

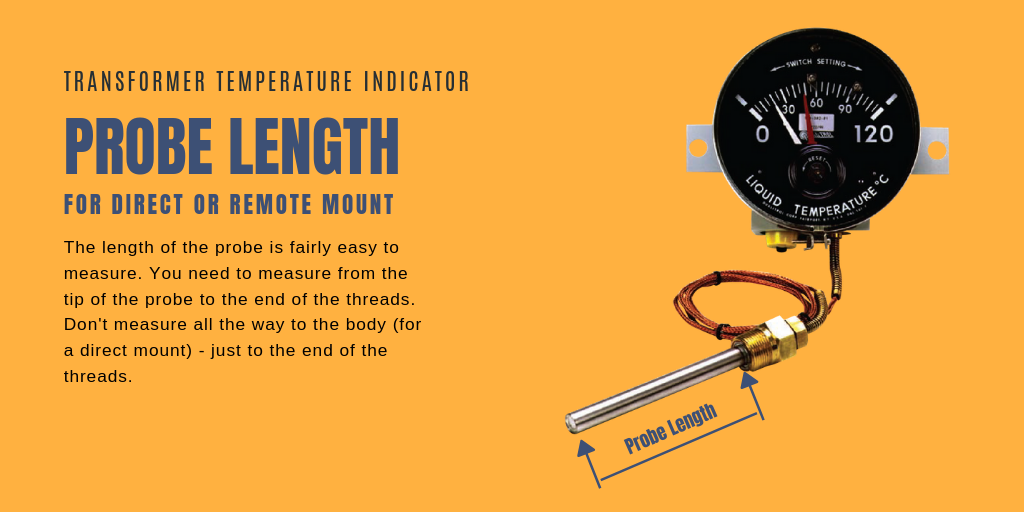

Probe Length

The length of the probe is fairly easy to measure. You need to measure from the tip of the probe to the end of the threads. Don't measure all the way to the body - just to the end of the threads.

Probe Diameter

The probe diameter is exactly what it says it is - the outside diameter of the probe shaft.

Probe Threads

The threads are a little more complicated, because you need to know the diameter and the pitch. As an example, you could have a ⅜ 18 NPT thread or a ⅞ 14 UNF thread.

You’ll commonly need a few tools to successfully identify the thread. There are a few good resources we can recommend that can help you in this process, if you’re not familiar:

Thread Type Identification Guide by Trimantec

Thread Identification Video from Swagelok

Additionally, we can provide adaptors to fit if you have a different size pocket (well) on the transformer. However, you will still need to know the thread diameter, thread pitch and the number of threads per inch.

Thermometer Switches (Contacts)

Type of Switches

Switches (aka contacts or relays) are used to send temperature and other transformer condition information to a control centre, for control and alarm functions. There are two types of switches you can get on a thermometer:

Form A

Form C

Form A switches are normally open (NO) contacts - just two wires.

Form C switches have two sets of contacts: one normally open (NO); one normally closed (NC). For these you will have three wires for each.

The way to identify whether you have Form A or Form C contacts is to examine the bottom of the connector output and count the pins inside. For example:

If you have one switch, and you can see two sets of pins, then it is a Form A switch.

If you have one switch, and you can see three sets of pins, you’ve got a Form C switch.

Number of Switches

The number of switches you can have on a transformer thermometer will vary by type and brand. On Qualitrol thermometers, you can have up to three contacts on a direct mount device and up to four contacts on a remote mount device.

The easiest way to tell is to look at the face of the dial. There you will see indicators - one for each set of contacts.

Gauge Dial Range

The dial range for the gauge will need to be defined when ordering. Here you specify the upper and lower limits you desire. Commonly winding temperatures will start at 0°C and go up to 160°C, or 0°C up to 220°C. Liquid temperatures will typically run 0°C to 120°C.

Thermometer Cable Length

As these thermometers are electromechanical devices, they all require electricity to run. A cable will be provided to fit into the bottom of the thermometer at one end, and into the control box at the other end.

You need to define the required length of this cable. It is best to specify a length that is a bit more than is required. That way you can always cut off any extra you don’t need, rather than not having enough and needing to order a new cable.

Capillary Length - for a Remote Mount Thermometer

On remote mount thermometers, the capillary length will also need to be defined. This capillary will run from the mounting point of the thermometer body to the mounting point of the temperature probe.

Obviously a capillary that is too short is a big problem. Another consideration is that capillaries should never be bent in a radius tighter than that of a 375ml soft drink can. So take this into consideration when measuring the required capillary length.

Also, be sure not to kink or cut the capillary, as the thermometer will be ruined.

Universal Gauges - Remote Mount

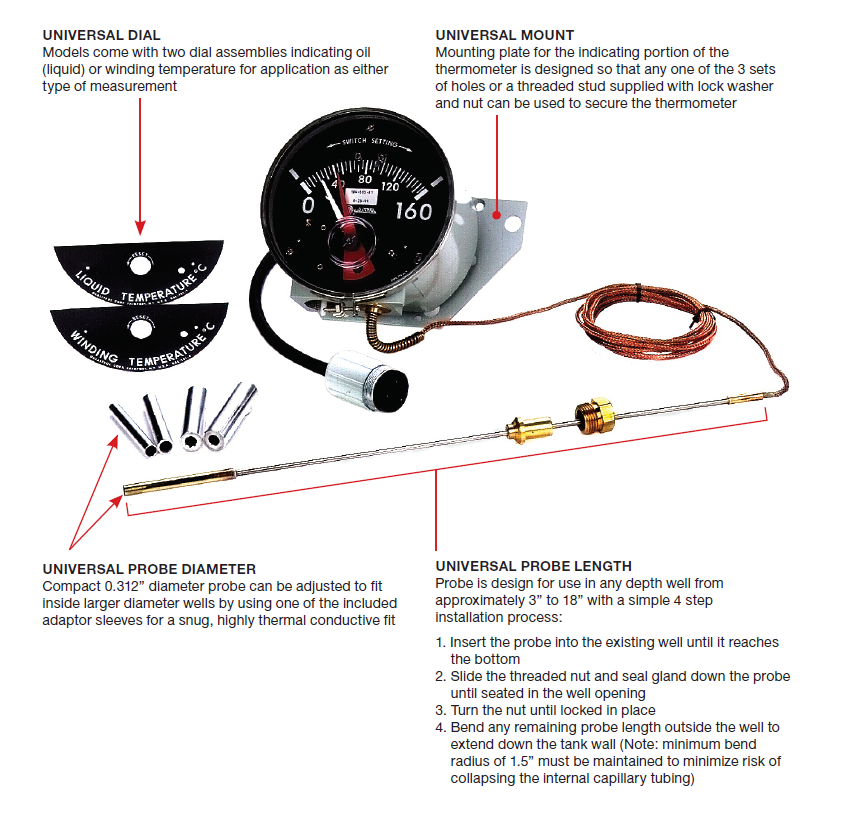

For remote mount thermometers, we also have a “universal” solution in the Qualitrol 104 series thermometers. The 104 series comes with a range of options, allowing it to be stocked by transformer owners for an “on-demand” retrofit solution.

2 Dial Assemblies - Can be used as a winding temperature or liquid (oil) temperature indicator.

Universal Mount - Mounting plate for the indicating portion of the thermometer is designed so that any one of the 3 sets of holes or a threaded stud supplied with lock washer and nut can be used to secure the thermometer

Universal probe diameter - Compact 0.312” diameter probe can be adjusted to fit inside larger diameter wells by using one of the included adaptor sleeves for a snug, highly thermal conductive fit

Universal probe length - The probe is designed for use in any depth well from approximately 3” to 18”. It is adjusted to the required length during install.

Up to four switches - user-adjustable switches featuring lockdown screws to reduce the effects of vibration and inhibit tampering

Replace a Direct Mount - you could even use a remote universal thermometer to substitute for a direct mount device if needed.

Check with an Expert

If you don't have the part number or are unable to adequately capture all the measurements we have listed above, the best course of action is to get in contact with an Insulect transformer specialist who will assist in identifying the right replacement part for your transformer.