How to maintain a Qualitrol AKM OTIWTI temperature indicator

Transformer OTIWTI maintenance, calibration and pre-installation information; for capillary based mechanical transformer oil and winding temperature indicators.

The Bulletproof OTIWTI

The Qualitrol AKM OTIWTI has been designed and built for a long life on a transformer in demanding outdoor conditions. They've done this for many decades, performing reliably on transformers the world over, in every environment imaginable.

Due to their robust design, there's not a whole lot of maintenance required to keep an OTIWTI in peak condition. They are made to be a largely maintenance-free device. However, to ensure maintenance-free operation, the initial installation on the transformer must be made with care. And there are some key checks to take into account for transformer asset management and regular transformer maintenance checks.

The Qualitrol AKM OTIWTI History

Before jumping into the technical side of things, we thought we’d let you know a couple of key statistics about the manufacturer of the AKM OTIWTI - Qualitrol - just in case you’re not familiar with the legacy of this tough device:

Over 75 years of experience designing mechanical temperature measurement devices for transformers

Over 250,000 capillary type thermometers in service worldwide in all environmental conditions

OK, now back to the article.

OTIWTI Pre-Installation Considerations

The best way to achieve correct operation and maximise longevity of your OTIWTI is to ensure that the device is correctly installed in the first place. This begins with performing some pre-installation checks and following correct handling procedures.

DAMAGES CHECK: Before installing an OTIWTI, check for possible damage from transport handling. If you notice anything, contact Insulect, your local agent or the manufacturer.

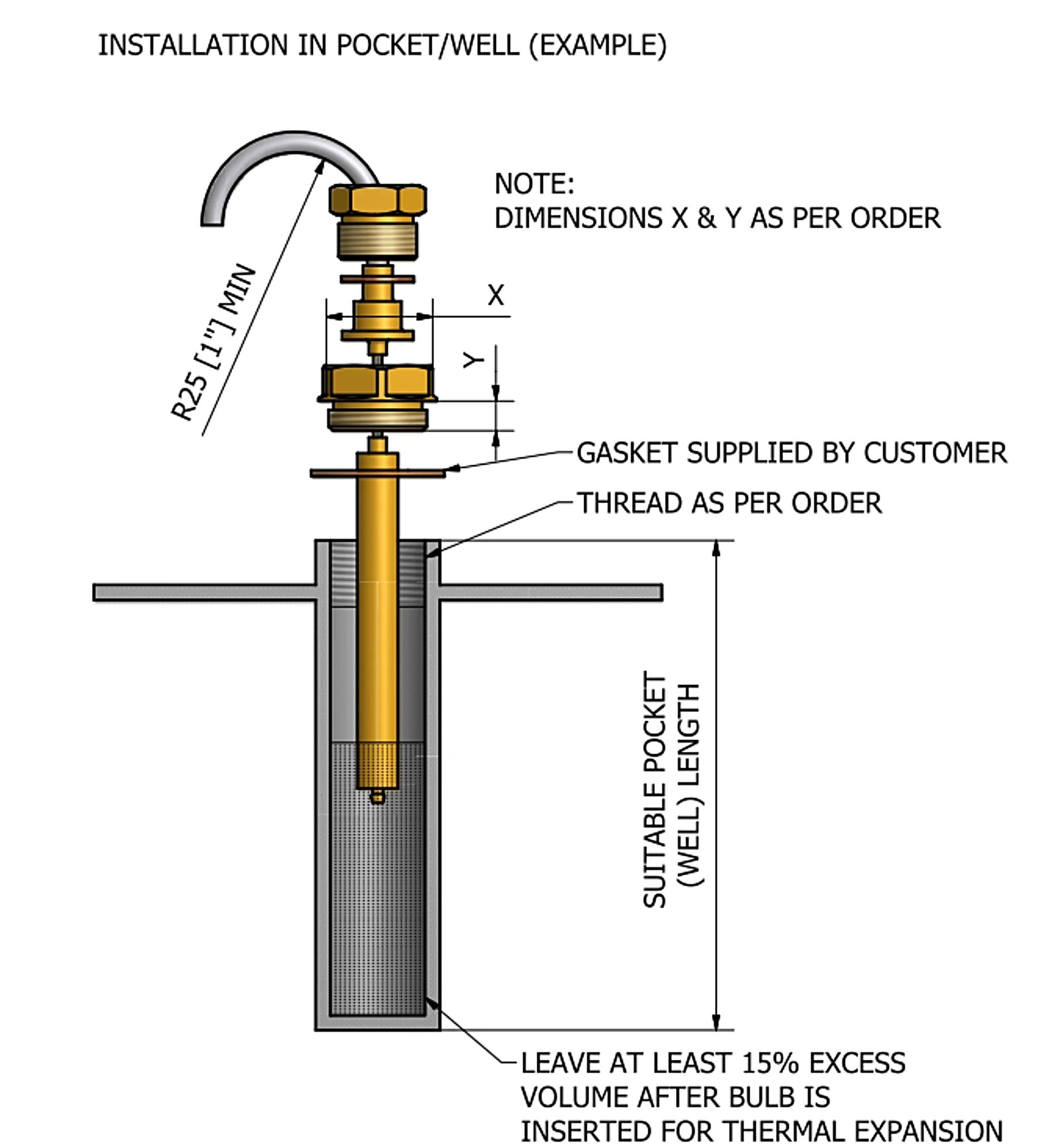

CORRECT HANDLING: Do not carry the instrument by the capillary. Do not twist the capillary when unwinding it, or bend too sharply – minimum radius is 25 mm. Clamp it along its entire length at approximately 400 mm intervals. Excess capillary can be wound in a spiral with minimum diameter of 100 mm.

THERMAL EXPANSION: Leave at least 15% thermal expansion space in oil filled pockets.

ANTI-VIBRATION MOUNTING: The non-vibration mountings included with the OTIWTI must be used to prevent mechanical wear out caused by transformer vibrations.

OPERATING TEMPERATURE: Consider positioning the device to avoid long exposure to direct sunlight where ambient conditions are high. Installation shall prevent instrument casing temperatures over +70°C for standard OTIWTI types.

Thermal Expansion allowance

Anti-Vibration mounting

OTIWTI Calibration

Each OTIWTI instrument is factory calibrated. Hence no further calibration is required for the life of the device, however a pre-installation calibration check should be performed to ensure that the device calibration is within tolerance limits, as follows.

Device calibration would be checked at 100 degrees Celsius, using a Dry Block Calibration Device or customer approved methodology.

OTIWTI Maintenance

Once your device is correctly installed and commissioned, there are only a couple of recommended checks from the manufacturer (Qualitrol), shown below. For these, a regular control is suggested as part of transformer asset management schedules, and where required, certain maintenance carried out.

Protection Class IP 65

To eliminate the potential condensation build up inside the instrument, the OTI/WTI is provided with two desiccant capsules. These can get saturated after a time in operation and a replacement will become necessary. The colour of the gel will change from pink (when new) into white (after saturation). If condensation is occurring inside the instrument, replacement of the capsules will be necessary.

Mountings with Rubber Dampers - Seismic Type and Universal Type

The vibration dampers on these mountings are made of Natural Rubber, NR, (also called Isopren). The expected lifetime of these parts is estimated to be a minimum of eight years. Since Natural Rubber will age faster when exposed to direct sunlight, high ambient temperatures or corrosive environments, we recommend a regular check of these parts. When the rubber dampers become old they should be replaced.

Please also note that it is important to mount these parts without any torsional stress.

More information can be found in the manufacturer's Instruction manual. You can download a copy of the Qualitrol OTIWTI (AKM 345) Gen2 Instruction Manual below.

That's all the manufacturer recommendations for installing, commissioning and maintaining your OTIWTI devices. If you follow these, you can expect your OTIWTIs to perform as they have for so many others - as expected from a world class, CE approved, fully weather-proof transformer temperature indicator.

If you require any further information on OTIWTIs, visit our product page, or contact our team.