Materials that will stand the test of time.

Composite materials really stand out in conditions that are harsh and demanding. Mechanically they are incredibly diverse and allow a broad range of applications to be met, often outperforming traditional materials.

Through our partner Rochling, we provide some of the best - and widest range - of composite plastics available in the world.

Bending Strength

Composites can vary greatly in bending strength (130 to 600 MPa) and elasticity (9000 to 30,000 MPa).

Compressive Strength

Compressive strengths up to 600 MPa can be achieved for applications such as structural supports for pipelines.

Impact Strength

When materials are exposed to high impacts, such as in frequently traveled areas or in work areas, composites can outperform metal.

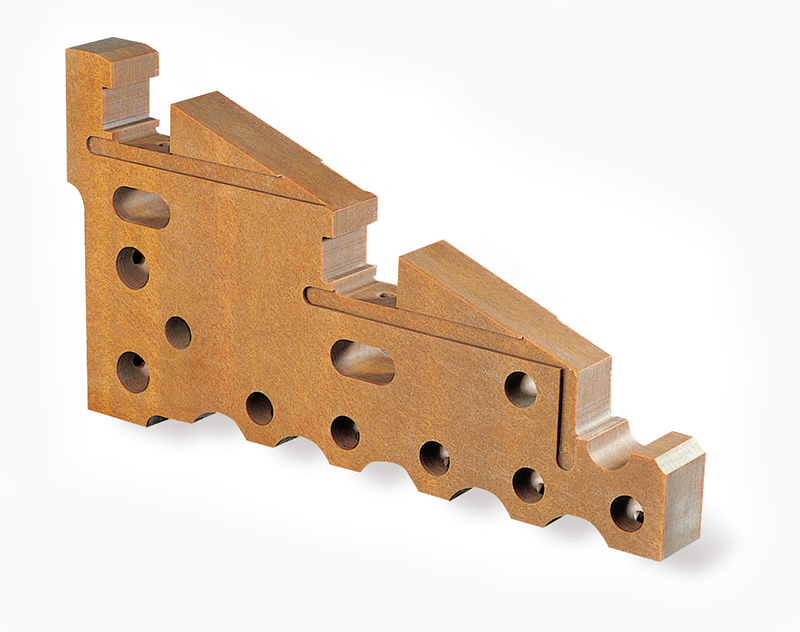

Tensile Strength

Even in applications where high tensile strength is a prerequisite, there are composite grades such as the fasteners above that can offer a solution.

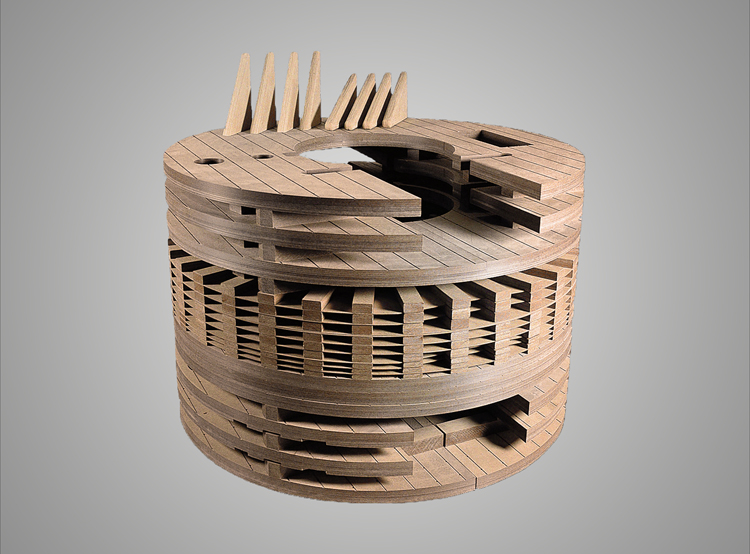

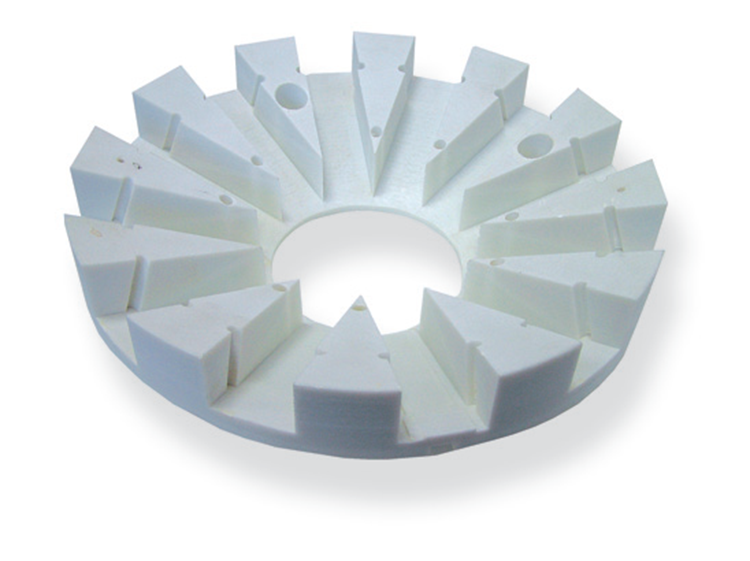

All shapes and sizes

We are regularly given a challenge by one of our customers to develop a new composite component for them, often to replace some other material.

We use various manufacturing processes available to our customers are as wide ranging as our range of composite materials - moulded sheets, filament winding and pultruding - as well as full finishing services.

More than just mechanically strong

For most applications, the required characteristics of a material aren't limited to mechanical performance. We can match up a material with your needs to ensure you get the required performance for the entire application.

Thermal

Electrical

Chemical

Moisture

Weather

Local machining and fabrication

Insulect’s manufacturing capabilities form a key part of the trusted service we offer our customers. Our two modern materials fabrication facilities – in Brisbane and Melbourne – work with a wide range of electrical, thermal and mechanical materials – including plastics, composites and cellulose-based products.

We offer short run, specialty or volume based machining and fabrication for almost any application and can produce cut-to-order sheets or finished components. Coupled with our highly-trained and experienced team, we are able to deliver on the most complex of customer requirements.

Materials for Mechanical Applications

The Latest News in Composites

Why Insulect is the right choice for Composites.

Quality Custom Materials

With our materials partner Rochling of Germany, we provide some of the best composites available. They have a large standard range and the ability to offer special formulas to customer needs.

Local Manufacturing

Modern, well equipped facilities in three states (QLD, NSW, VIC) give us the flexibility to meet varying customer demands, whether for highly complex or high volume projects.

Expert Advice

We've been in the engineering materials world for over two decades. Our team can work with you to solve a wide variety of challenges and technical applications.

Local Support

Whether you have a new enquiry, are planning a large refurbishment or need support for the life of a project, we are just around the corner and can support you all the way.

Also in Industrial:

Electrical Materials

Thermal Materials

Pultrusion Composites

Composite Fasteners

Find out more today.

Whether you're operating a Transmission or Distribution network, a Generation plant, or Industrial site, we would be glad to have a no obligations discussion to understand how we can help your organisation.