Transformer Ester Fluids by Midel.

Transformers are often cited as one of the top five high-risk assets. Accordingly, Midel fluids are helping to safeguard these critical assets for transformer OEMs, Utilities and industrial asset owners.

Midel’s natural ester and synthetic ester fluids enable transformers to work harder (at 20% overload), for much longer. They provide unrivaled risk mitigation through their high fire points and, compared to mineral oil, superior moisture tolerance. In addition, these ester fluids are readily biodegradable and non-toxic, presenting no threat to the environment.

Why use an ester fluid in transformers?

Cost Savings

Advantages of Midel ester fluids, such as their high fire and flash points, biodegradability, oxidation stability and excellent moisture tolerance, are acknowledged throughout the power industry and lead directly to cost savings.

Fire Safety

Midel fluids have an impeccable fire safety record – they are classed as less flammable fluids for dielectric purposes, meaning they require lower fire safety measures than mineral oil. Midel’s fire safe properties allow for their use indoors and in other critical areas where mineral oil would not be acceptable.

Environment Protection

MIDEL ester transformer fluids are fully and readily biodegradable, unlike mineral oil. They present a much lower risk to the local environment if spillage occurs. Using Midel ester fluids may also reduce the need for containment around the transformer, thus reducing the amount of real estate needed.

Business Continuity

Midel fluids helps mitigate risks for critical power infrastructure, making a valuable contribution to a robust business continuity strategy. They are a critical part of a move towards the adoption of more effective materials used to safeguard transformers and power supplies.

Retrofilling with ester fluids

Retrofilling is the process of replacing the existing insulating fluid (e.g. mineral oil) in an operational transformer with new fluid. Doing so effectively upgrades the transformer.

When retrofilling also involves the use of an advanced fluid such as synthetic ester fluid or natural ester fluid, it then delivers further demonstrable benefits.

Dissolved Gas Analysis and Ester Fluids

Like all transformer oils, Midel ester fluids can be tested during operation in order to spot any possible faults before they become serious.

One of the ways this is done is through Dissolved Gas Analysis (DGA), where the identification of key gases and rate of gas production can be used to determine the nature and severity of any problems with your transformer.

Transformer Ester Fluids

Synthetic Ester and Natural Ester

The Latest News in Transformers

Insulect works inside and outside of Transformers.

Specification Development

We work closely with end user teams to understand their challenges, network needs and existing asset base, so to help guide future specifications and investment decisions.

System Commissioning

Our team can support system setup, from integration with existing architecture, through to installation and commissioning.

Expert Advice

From the insulation system, to key transformer components and monitoring applications, our team has plenty of insight into the complexities of transformer management.

Fleet Maintenance

We offer a range of services to support the lifetime operation of monitoring hardware and can customise this to suit individual networks.

Also in Transformers:

Transformer Monitors

Sensors, monitors and controllers for integrated transformer monitoring, data capture, analysis and fleet management

TRANSFORMER PROTECTION & MEASUREMENT

Devices for pressure, moisture, oil level, oil temperature, gas accumulation

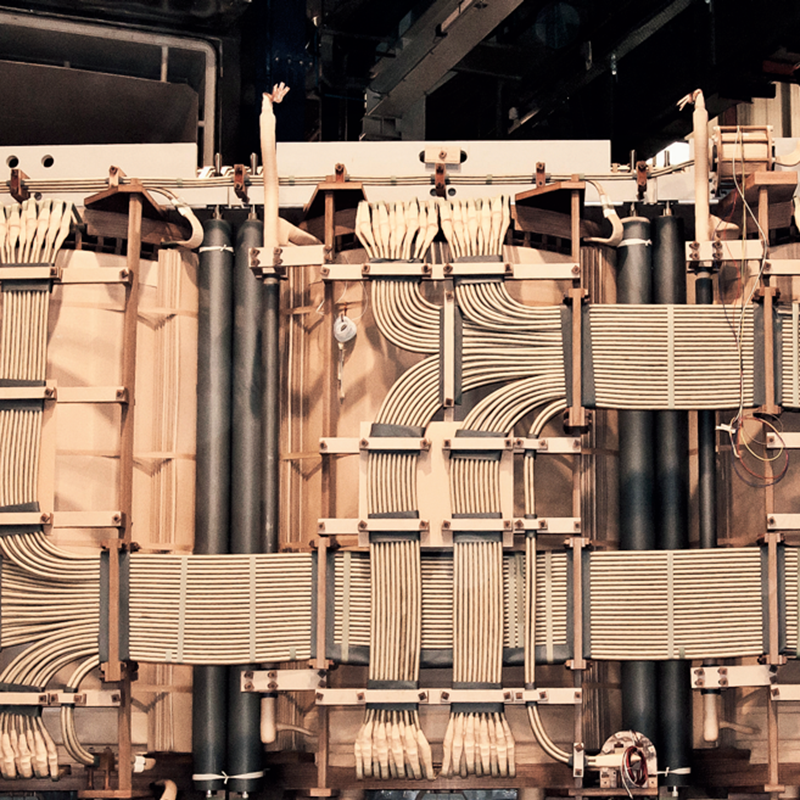

TRANSFORMER INSULATION

Cellulose and composite insulation products

Find out more today.

Whether you're operating a Transmission or Distribution network, a Generation plant, or Industrial site, we would be glad to have a no obligations discussion to understand how we can help your organisation.